The Crucial Role of High-Quality Fasteners in Aerospace Vehicle Integrity

Aerospace fasteners, essential components in aviation and space technology, play a crucial role in securing hardware for flight. These small yet vital parts are sourced from trusted distributors committed to advancing the field and improving component quality. They provide a robust clamping force, ensuring the integrity of connections between diverse materials on aircraft and spacecraft. As aerospace vehicles face the challenges of high speeds, fluctuating temperatures, and pressurized conditions, the quality of fasteners is paramount for safety. Meticulously designed and tested, these fasteners safeguard crew, passengers, and valuable payloads during flight.

The Engineering Behind Aerospace Fasteners

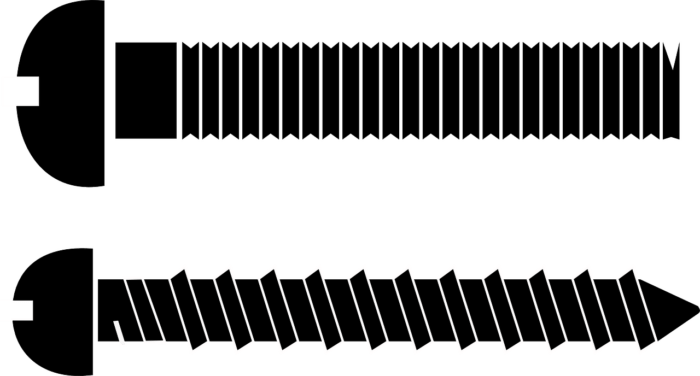

In the realm of aerospace engineering, the fastener is more than a mere bolt or screw; it is a critical component meticulously engineered to sustain exceedingly precise performance requirements. Material engineers and hardware distributors are hard at work creating cutting-edge alloys and developing treatment processes that elevate the resilience of fasteners to unparalleled levels. The outcomes are fastening solutions capable of enduring the formidable forces encountered during launch and flight and maintaining their structural integrity over countless service hours.

Safety Protocols and the Utilization of Aerospace Fasteners

Safety protocols are paramount in aviation and space exploration, weaving through the narratives of technological advancement and exploration. Aerospace fasteners, while often overlooked, are essential components that undergo rigorous checks to meet the aviation industry’s stringent safety norms and certifications. They serve as vital links between technology and safety, ensuring the viability of flight by securely holding together critical components. Despite their lack of prominence, these fasteners play a starring role in guaranteeing the performance and safety of aerospace vehicles.

Expert Insights on Aerospace Fastener Innovation

The aerospace sector is deeply ingrained with a culture of unwavering innovation and unrelenting perfectionist pursuit. Specialists in the domain remain unwavering in their conviction that meaningful performance gains are found in the details, such as fastener quality. Organizations like NASA lead the charge, whose stringent testing protocols demonstrate the vital role fastener quality plays in the overall success of aerospace missions. These echoes of knowledgeable observations highlight the need for ongoing improvements in fastener technology. The saying that “the smallest screw can have a seismic effect on the aerospace industry” is not hyperbole. Although the general public frequently ignores aerospace fastener innovations, the industry views them as enormous advancements in efficiency and safety. As emerging technologies like additive manufacturing and novel metal composites make their way into fastener production, industry experts are particularly optimistic about these innovations’ promise for furthering aerospace design and reliability.