How to ensure productivity and efficiency of your equipment’s at your workplace

Time is money and managing time is the key of a successful business. The more production you can extract in a period of time, more money you will make. To produce more and efficiently you should have proper equipment at workplace. TPM consulting is one of the best management systems for an organised approach to improve efficiency, reliability and productivity of the equipment in any organisation.

If you are struggling with production or efficiency issues there are several things you can do to increase it without sacrificing on quality by just recognising the obstacles and reorganising the way you work.

Examine the Existing Workflow and Stay Organised.

First thing is to examine the work flow and pain point that need to be organised. Analyse working trend, people, technology and production process. Once you have done the analysis and found the issues, its time to consider using value mapping which is an effective solution for identifying projects for process development.

The time wasted because of lack of organisation impacts the entire company, be careful in analysing the issues in your organisation and in the major equipment used. Sooner you will realise, sooner you will be able to resolve it. Stay organised, a best practice to enhance the productivity and efficiency.

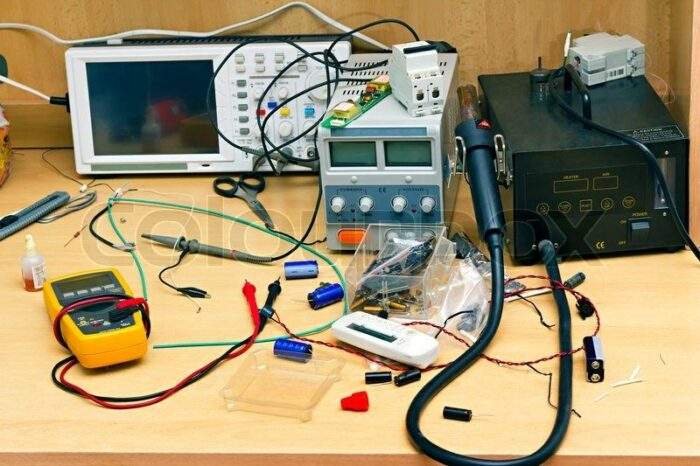

Get Smarter Machining Tools.

Machines play a vital role and an employee can be as productive as his/her tools are.

So be super careful in investing. Equipment can be costly while installing and then training employees, but it is important to go for good tools ignoring the price. It is be beneficial in long run and gives your company a competitive edge. Also, upgrading your equipment and tools time to time is important to cope up with the latest market trends and growth.

Provide Right Equipment

Getting smarter tools are important but deciding the right equipment based on your team’s skills are mandatory, choosing right tool will make their work easier, production efficient and process streamlined. You can also automate manual tasks, which will help in freeing up manpower to work for other meaningful task and saving the cost.

But make sure to select equipment’s that are beneficial and easy to handle. Also buy them from reputed brands, they will be good at work along with after- sales support to ensure your business run smoothly.

Keep updating Process and Technology

Providing right equipment is not enough, once you are well equipped with the machine. Keep reviewing and mapping your existing workflow to identify areas or process where updates are available in the market, specially the tools that are placed from long time without any updates.

Updating equipment will improve production speed and quality, while ensuring productivity and efficiency of your equipment’s at workplace.

Invest in Training and development.

You have purchased the top brand equipment’s, but your employees are not trained to use them. It will not do any good. Don’t risk with it and do arrange the regular employee trainings to check and upgrade their knowledge of the tools.

Also, there are different type of trainings that can help employee in learning to deal with various issues that can come on their way, such as TPM consulting training and implementation not only increase the production by improving the efficiency of equipment but also help in increasing employee confidence and job satisfaction.

Market is upgrading every second with new technology and equipment, so it became mandatory to keep your employee upgraded to deal with latest competitions.

Timely Cleaning and servicing of Equipment

Your equipment needs timely cleaning and servicing to work efficiently which will minimise the wear and tear on machines and save your money while extending the overall life of your equipment, which will be otherwise wasted on repair or replacement of parts. Invest a budget to take the preventive measures because the new tools can boost productivity, but it also requires timely maintenance to ensure it continues working at optimum level. Also, it is important for your employee to know the basic trouble shooting steps, so that they can find the root cause of the errors.

Inspection and Maintenance Schedules

Inspection and Maintenance Schedules are vital to keep machinery running at full capacity.

The type of Inspection and Maintenance depends on the type of equipment used, how regularly you use them, and on the guidelines of manufacturer. If you will be able to identify the problems at its starting, you can prevent the major setback which can be a costly affair if left untreated.

Replace Outdated Equipment

Replace outdated equipment that can’t be repaired or updated. You may be trying to save your money by using the old one, but it is causing you more harm then good.

Because with outdated software’s or tools your employee can’t be as productive as they can be with the right updated tools. In case of machineries you will end up wasting money by not replacing broken machines, constant repair expense can eventually add up and demotivate the employee.

Evaluate how much they are costing you during repairs, downtime, and production output. Then compare how much new machinery will cost while increasing the output and lowering the costs.

Set realistic expectations and Encourage team-work

Setting certain expectation is a right thing but over burdening your employee may lead to the dissatisfaction, be careful in setting the deadlines for any project, don’t be unrealistic in deciding the timelines while ensuring punctuality, high-quality output and safe procedures.

The reason behind success of any organisation is its team, it’s never a single-handed effort. The company is most productive when everyone works together towards the same goal. It is important to focus on work, but it is crucial to know that every member should feel comfortable as part of the team, the better understanding and camaraderie they share better results and working culture you will get.

Irrespective of the size of organisation boosting productivity is important to enhance gross profits and maintain competitiveness. Productivity is affected by combination of tools, processes and employees.

You must work in accordance with the improvement in all areas which requires examining current practices, upgrading the tools and training the employees timely to optimise the performance and efficiency.