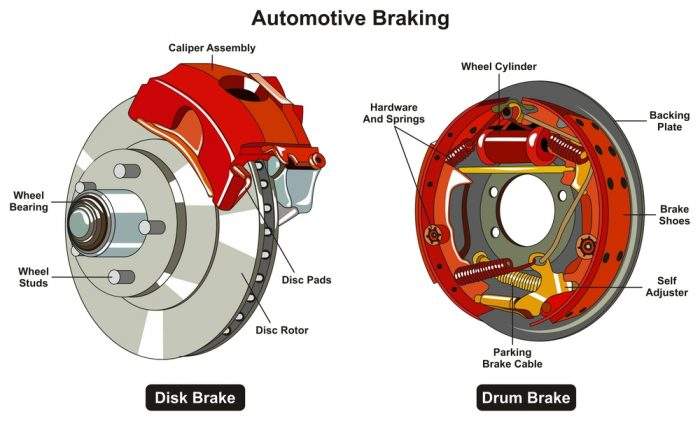

Drum Brakes: What Are They Made Of? How do they work?

Most of us probably know how disc brakes work. But what about drum brakes? The operation of these more humble pieces is almost certainly something less known. Something that has not helped the fact that their use in vehicles has decreased over the years. They have been used since 1902. Relegated to being installed in the most miniature cars and with modest engines.

If your model equips them, it is always on the rear wheels, with disc brakes at the front, since they only have to take care of 25-30% of all the stopping power in that location. Drum brakes have more components, but they are also cheaper to make and even bring certain advantages in electric vehicles. To understand this type of brake in detail, we must first know its various parts and functions.

Let us get all the information about drum brake from RCC Auto Transport.

What is a drum brake made of?

The drum brake can look complicated, and it can be pretty intimidating when you open one. However, once you find the rationale for each component, understanding how it works is complicated. These are the main parts of a drum brake:

Drum

It is the moving part that covers all the entrails of the braking system and remains anchored to the wheel. It is often made of cast iron and is resistant to heat and wear. This is what you see when looking at a mounted drum brake, and it is the component on which braking force is applied to slow down or stop the vehicle.

Brake Shoes

Used as a surface to press on the inner face of the drum and create the friction necessary to stop any vehicle. They are made up of organic or metallic (steel) composite materials that contact the drum and wear out with use. Each of them contains two shoes: the main one, closer to the front of the vehicle, and the secondary one, in charge of the rear. Depending on the type and brand, they can be interchangeable.

Hydraulic Cylinder

Thanks to the brake fluid, a pressure is exerted that causes the pistons to keep the brake shoes at a constant distance from the drum, either to press them against the drum wall or to retract them, even when the lining wears. It is attached to a master cylinder that contains a piston that moves outward when force is exerted on the brake pedal and forces the shoe towards the inner surface of the drum.

Return Springs

They are responsible for retracting the shoes after pressing the brake. There are two: one for the primary shoe and one for the secondary shoe. They must be strong enough to carry out their mission but not too strong to hinder braking.

Adjustment Mechanism

Maintains minimal clearance between the shoe and the drum, so they don’t come into contact when the pedal is not depressed. If the former wear out and the space between them and the drum increases, it can be adjusted again to keep the space inside. Once adjusted, it keeps the same gap on its own.

Plate: it is the part where the internal components of the drum brake are fixed: the cylinders, the springs, the adjustment mechanism, and the shoes.

How does a drum brake work?

Drum brakes work according to the same principle as disc brakes: two elements that act as friction components ( shoes ) and a piston that pushes them against an area that rotates jointly with the wheel ( drum ) thanks to a circuit hydraulic. But it also has an adjustment mechanism, that of the parking brake and many springs. When you step on the brake pedal, the piston pushes the shoes against the drum. That’s simple, but why do we need all those springs? This is where it gets a little trickier.

Many drum brakes come on automatically. When the shoes contact the metal surface, a wedging action occurs that has the effect of pressing the shoes with more force. That extra braking force allows a smaller piston to be used than disc brakes, but the shoes must clear the surface when the pedal is released. This is why the recovery springs, helping to keep them in place and return them to their rest position after fulfilling their function.

How to Make it Function Correctly

To function correctly, the shoes must remain close to the drum without touching it. If they go too far apart (as the shoes wear, for example), the piston needs more fluid to travel that interval, and the brake pedal will go down further when you apply the brakes. That is why most of these systems have an automatic adjustment mechanism. Some cars are equipped with one that activates when the handbrake is applied and can become out of adjustment if not used for long periods; it must be moved with a certain periodicity.

The parking brake must be actuated by a different energy source than the primary braking system. The design of the drum allows an actuation mechanism by a simple cable from the lever, puller, or pedal itself, depending on the model. When this is actuated, the cable pulls a lever that separates the two shoes from the drum core.

And mentioning this last aspect, the drums are also not great when managing high temperatures: with all the components inside a metal frame, the accumulated heat has nowhere to go. An increase in temperature means a reduction in friction, which makes the brakes less effective. Nor will they work most suitably if they are soaked with water inside.

Do drum brakes need maintenance?

Being more complex than disc brakes, they do require a bit more maintenance in terms of investment of time, because as such, they are not components that need a lot of care. The most common thing required for drum brakes is changing the shoes. Some have an inspection hole on the back, where you can see how much material is left. These should be replaced when the friction material is below 1.6 millimeters from the backing plate.

As with discs, drums can have an uneven braking surface if a worn brake shoe is used for too long; the rivets that hold the abrasion material to the plate can wear away some grooves inside. Sometimes, a badly scratched drum can be repaired since the contact surface is inside the drum; as you sand, the diameter increases. Each one can cost between 50 and 100 dollars, although it depends on the size and model.

How often do you have to change the drum brakes?

The drum brake housing is designed to last 250,000 to 300,000 kilometers under normal conditions before friction causes its inside diameter to increase enough to affect brake shoe contact. In general, the latter can travel around 60,000 km before they wear out and need a replacement. Aside from replacing worn parts and ensuring you have the proper amount of brake fluid, little additional maintenance is required.

Advantages and disadvantages of drum brakes

Advantage:

- Cheaper to make than disc brakes.

- Drum friction pads have more surface area and last longer than disc calipers.

- Unlike disc brakes, they have a “self-energizing” ability to take advantage of their geometry to increase stopping power without increasing pressure.

Disadvantages:

- They are not as good as disc brakes at handling high temperatures.

- They do not work correctly if they are wet inside.

- Maintenance requires more time compared to disc brakes.

- The asbestos coating on the brake shoe is harmful to humans.

We hope You have got good information about the drum.