Stripping Pins’ Role in the Die-Cutting Process

Manufacturing processes around the globe are meant to generate moderate to heavy amounts of waste. Hence, the reduction of waste is one chief area where key manufacturers are eyeing to make a difference.

Now, waste management is seemingly one such area that has different consideration levels. Going by the data of global manufacturing, die-cutting and making seem to be the most widely used processes.

On several occasions, scrap removal forms an integral part of die-cutting that not only damages tools, but also leads to an imperfect end product. This further leads to increased production costs.

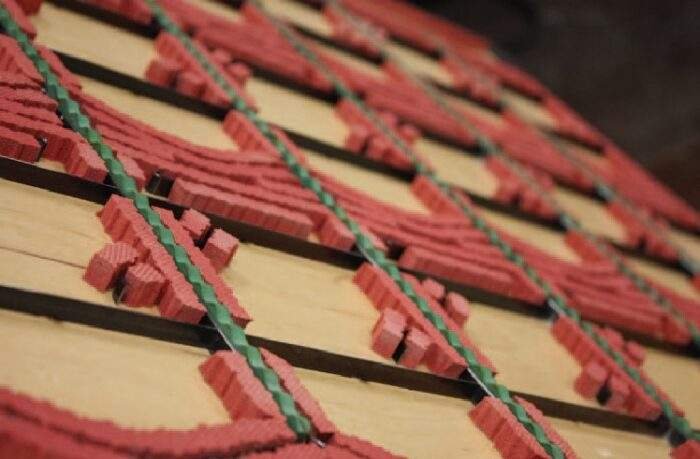

Stripping pins are an excellent tool that is used in die-cutting and die making across the world to enhance scrap management. They come in a variety of shapes and sizes and fit snugly to offer maximum leverage for any manufacturer.

Read on to find out more about the role of stripping pins and how they contribute towards bettering the die-making and cutting process.

What Makes Scrap Removal So Important?

In die making and cutting, a significant part of raw material invariably goes for waste. Now, such scraps can appear in the shape of small dents or holes or an entire shape that does not match the symmetry.

Scrap management is generally carried out in two ways namely; manual and automatic. As the name suggests, the manual process involves human labor to remove all wastes. On the other hand, the automated process of scrap removal employs stripping pins that remain fixed to the machine reserved for die-cutting.

Remember, the accumulation of scrap across any kind of manufacturing process poses a threat to financial loss. Not the end product falls short of the mark, but the post-production budget also goes beyond the limits.

In essence, not having a scrap removal system in place can lead to :

● Damage to tools and equipment -A lot of times, we get to witness the scrap accumulating right within the die cavity. If it’s not removed at once, it builds great pressure that can damage the die-cutting blades. Thus, it slows down the manufacturing process which in turn increases the cost of production.

● Improper finish – Several times it so happens that parts of scrap get caught between the die bearers and the anvil. As such, it becomes difficult for the tools to function at the desired speed. Further, it also leads to improper and uncut parts. Such an end product ultimately needs to be done away with, and can dramatically impact the cost of production, especially when the material is an expensive one.

● Increased Cost of Labor -While engaging human labor for scrap removal is always an option, the choice remains highly debatable. Apart from the initial costs of hiring labor solely for the purpose, you will need to additionally employ some personnel to supervise the process. Comparatively, investing in automated scrap removing machines make way for smooth functioning, mitigating human errors, and doesn’t add up to production costs.

The Role of Stripping Pins

Stripping Pins are seemingly one of the most effective scraps removing tools available today. They are attached or placed right along the anvil and function to penetrate the slug and pass it onto the comb to dispose of. Owing to their high rotating speed, stripping pins are also capable of removing the scrap from external matrices too. The following points go in favor of stripping pins acting as a scrap removal system:

- They are detachable and can be replaced by a new one, as and when needed.

- They ensure complete scrap removal.

- Even though they rotate at high speeds, they do not harm any tools or equipment involved in the core manufacturing process.

Some of the popular types of stripping pins include the following:

- Standard Pins -Available in several different shapes and sizes, standard pins measure anywhere between 2mm to 20mm. They are generally preferred to give shape to a wide number of uses like drilling, making holes, laser cutting, and much more. It is the size of the base pin that remains constant and makes it advantageous to work with standard pins.

- Stripping claws– Stripping claws are believed to be one of the most economical equipment reserved for scrap removal at high speed. They are quite different in structure from standard stripping pins and measure at about 50mm in length and carry a wide mouth.

- Multi-Point – One of the most effective types of stripping pins that is available in the market, multi-point stripping pins carry sharp edges to remove scraps efficiently from even the most tricky and smallest areas.

- Lower Stripping – Similar to stripping claws, lower stripping pins are also capable of functioning at high speed. They are mostly used to take care of scraps and slugs.

Wrap up