7 Features of Aluminum Profiles that Make it Perfect for Framing

Did you know aluminum framing systems are suitable for most commercial, engineering, and industrial applications? It is a magic metal mainly found as a Bauxite ore element. Aluminum framing profiles are used to craft automated linear systems, robotic systems, enclosures, and material handling systems.

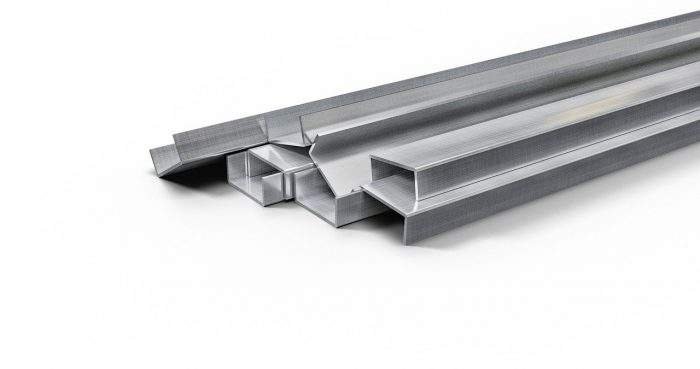

Aluminum framing systems such as the Mini Tec profile systems are crafted using the extrusion process. The aluminum is forced through a die to create an aluminum profile. The profiles are assembled and interconnected to form the frame. The machinability element of the aluminum profile allows the designing of complex sections and structures.

Modern-day aluminum alloy comprises excellent mechanical, chemical, and physical properties. This has necessitated an increase in the use of aluminum. Additionally, aluminum profiles encompass beneficial features such as;

1. Light-weight

Aluminum is one of the lightest commercial metals available, weighing 2.7 g/cm3. The metal weighs about a third of steel/copper. Due to the lightness element, aluminum doors and window frames can be easily assembled.

2. Highly recyclable

Aluminum is a unique metal with 100% recyclable ability. Recycled aluminum doesn’t degrade quality. The metal can be recycled repeatedly and still look like pure aluminum; hence industries can easily maintain the supply. It takes 14,000 kWh to produce 1 tonne of new Aluminum, while only 5-10% of the initial wattage must re-melt and recycle the same amount of Aluminum.

3. Easy to increase the tensile strength

Pure Aluminum encompasses 90MPa tensile but can be increased up to 690 MPa by alloying with other elements.

4. Corrosion resistance

When aluminum comes into contact with air, a protective layer of aluminum oxide is formed. Due to this property, structure owners can easily maintain aluminum window frame surfaces. The aluminum oxide layer is resistant to acid rain, cleaning products, and corrosion.

5. Readily form alloys

The aluminum profile can be alloyed with other elements to improve physical properties. Manganese can be alloyed together with pure commercial aluminum to increase strength by up to 20%. Other possible alloys encompass metals such as copper, silicon, zinc, magnesium, and iron. Extruding aluminum profiles may integrate silicon and magnesium to build glazing frames.

6. Malleable and ductile properties

Aluminum can be bent and pressed into a shape. It can be drawn out into a thin wire without breaking, cracking, or losing its toughness. These properties necessitate the designing of curved window and door frames at ease.

7. Decorative elements

Aluminum frames can be coated for a textured finish using powder coating machines or anodizing components. Anodizing is carried out by immersing the aluminum profile in an acid electrolyte bath then passing an electric current through it. The anodizing process forms a durable, decorative, and corrosion-resistant aluminum oxide surface.

Conclusion

The crafting of glazing and framing systems using aluminum profiles rises every year by up to 5%. Aluminum frames can be further protected by anodizing and powder painting the surfaces. Structures made from aluminum can withstand extreme weather conditions; thus, no need to worry about cracking, swelling, splitting, or warps.

Aluminum can integrate a wide range of metal alloys to tailor specific applications. Since aluminum is pliable, industries can easily bend aluminum frame profiles into the required shape without breaking.