How Barcode Systems Enhance Visibility Across Complex Supply Chains

In today’s global economy, managing supply chains has grown increasingly complex, with multiple touchpoints, vast inventories, and ever-changing consumer demands. To maintain efficiency and accuracy, businesses rely on real-time data to monitor goods from production to delivery. One of the most effective ways to achieve this is through automated tracking systems that reduce human error and streamline operations.

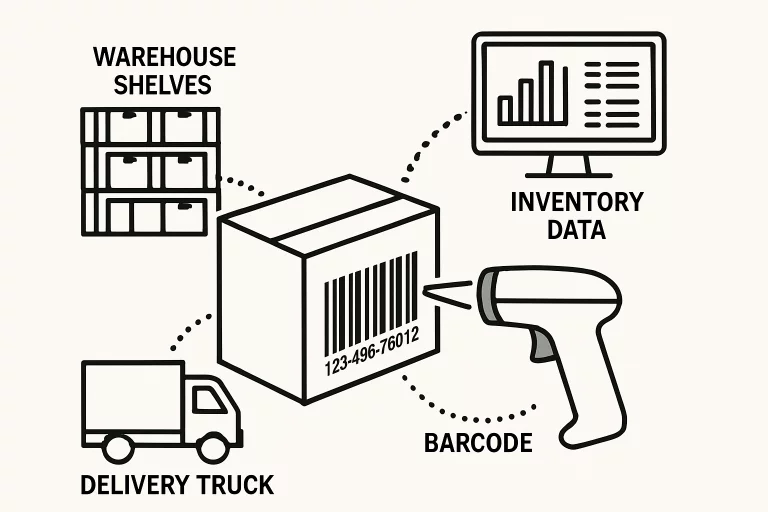

Barcode technology plays a vital role in providing clear visibility at every stage of the supply chain. Companies can instantly access location, quantity, and movement data by assigning a unique code to each product or shipment. Tools like an inventory barcode scanner allow quick identification and updating of stock levels, improving coordination between warehouses, retailers, and logistics providers. As a result, businesses can respond more effectively to disruptions, minimize delays, and make data-driven decisions that enhance overall performance.

Enhancing Inventory Accuracy

Traditional inventory management faced challenges like manual counts and inaccuracies. Barcode systems have transformed this by providing a unique digital identifier for each product, enabling rapid, accurate tracking. Scans update inventory records in real time across warehouse systems, achieving accuracy rates over 99%, which was difficult with manual methods. This accuracy reduces costly mistakes such as stockouts and overstocking, empowering supply chain managers to optimize reorder points and reduce holding costs. Ultimately, it transforms inventory into a strategic asset, enhancing service reliability and cash flow.

Streamlining Operations

Barcodes enhance transaction data capture and processing throughout key supply chain workflows, such as receiving, order picking, packing, internal transfers, and outbound shipping. Scanning a barcode is faster, more precise, and less error-prone than manual data entry, leading to greater efficiency.

For instance, a leading European third-party logistics provider revamped its operations with industrial barcode printers and handheld scanners, reducing order picking time by 35% and improving inventory accuracy. This allowed for quicker onboarding of new customers without disrupting operations, resulting in faster order processing, improved fulfillment reliability, and higher customer satisfaction. Real-time data sharing with connected systems enables businesses to swiftly adapt to changing order volumes and minimize interruptions.

Improving Supply Chain Visibility

The ultimate goal is to achieve comprehensive supply chain visibility: monitoring goods at every stage, across continents and partners, from the initial manufacturing phase to the final delivery. Barcode technology plays a crucial role in this vision, as each scan records the time, location, and product status in a unified digital system. When aggregated and analyzed in real time, these records offer organizations exceptional insight into the precise location and condition of their stock, whether in transit or at rest.

This transparency brings enormous operational benefits. Sharing barcode data among manufacturers, transport providers, distributors, and retailers helps organizations quickly detect bottlenecks, trace misplaced products, and plan optimized handoffs between partners. When all parties have up-to-date, reliable inventory and logistics information, decisions can be made proactively to mitigate disruptions, reroute shipments, or adjust orders on the fly. Such visibility improves efficiency, trust, and accountability among all supply chain partners, which is especially critical in today’s fast-paced, interconnected environment.

Cost Reduction and Efficiency Gains

The automation provided by barcode technology is directly associated with significant cost reductions across the supply chain. By eliminating the need for labor-intensive manual entry and significantly reducing the risk of errors, barcode scanners allow companies to reallocate valuable staff to higher-value tasks. This increase in efficiency boosts throughput and minimizes costly issues like returns, corrections, or shipping errors. As a result, businesses experience tangible and intangible savings, including reduced overtime, fewer required stock audits, and lower costs related to excess inventory or disruptions.

Streamlined processes made possible by barcode technology shorten lead times from order to delivery, heightening overall resource utilization and boosting output per employee. In an era when margins are slim and customer expectations are high, the ability to fulfill an increasing number of accurate, on-time orders without scaling labor costs provides a strong competitive edge and a healthier bottom line.

Ensuring Compliance and Traceability

In industries where product safety and regulatory compliance are paramount—such as food, pharmaceuticals, and consumer goods—tracking every detail is vital. Barcodes provide a secure, auditable record for each item, capturing details such as batch numbers, lot codes, timestamps, and expiration dates throughout its life cycle. This complete traceability is a cornerstone of both quality assurance and risk management.

When incidents arise, such as product recalls or quality investigations, businesses implementing comprehensive barcode systems can pinpoint affected products instantly, trace affected batches, and rapidly alert partners and regulators. Rather than relying on patchy manual records, barcode traceability ensures compliance with laws and standards while protecting the organization’s reputation. This robust data trail strengthens consumer confidence, as customers increasingly demand brand transparency and accountability.

Integrating with Emerging Technologies

Forward-thinking supply chain leaders are using barcodes as a foundation for integrating even more innovative technologies. For example, the Internet of Things (IoT) connects sensors to barcode systems, allowing environmental data—like temperature, humidity, or shock—to be automatically associated with each product for real-time monitoring, quality control, and predictive maintenance.

Blockchain technology represents another powerful integration. By creating a tamper-proof record of each transaction and movement, blockchain provides unquestionable authenticity for products, streamlining regulatory reporting and simplifying complex audits. With IoT and blockchain working alongside barcoding, organizations gain an end-to-end digital view of every supply chain event, improve risk assessment, and use predictive analytics to stay ahead of market changes.