Essential Safety Tips for Efficient Material Handling

Key Takeaways

- Implement ergonomic practices to reduce the risk of musculoskeletal disorders.

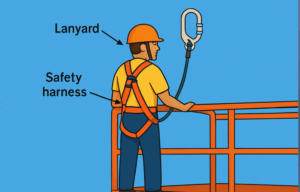

- Utilize appropriate personal protective equipment (PPE) to safeguard workers.

- Incorporate mechanical aids and motorized solutions to minimize manual handling risks.

- Provide comprehensive training on safe material handling procedures.

- Maintain organized and clean workspaces to prevent accidents.

- Regularly inspect and maintain equipment to ensure safe operation.

- Leverage technology for remote monitoring and automation to enhance safety.

Material handling is a foundational aspect across a wide range of industries. The movement, storage, and protection of goods often require coordinated workflows and careful attention to safety. Prioritizing efficient material handling practices leads to safer work environments, fewer injuries, and a lower risk of costly disruptions. Companies achieving the best results typically rely on the right tools, such as 5 inch caster wheels, and implement robust safety protocols.

Understanding and adhering to proven safety strategies is essential. Not only do these measures protect workers, but they also preserve productivity and minimize downtime. Even simple modifications, like adjusting how materials are moved or clarifying workspace organization, can yield significant benefits for both employees and operations.

Prioritize Ergonomic Practices

Ergonomics is the science of designing jobs and work environments to fit workers. In material handling, applying ergonomic principles helps prevent chronic injuries, such as strains or sprains associated with lifting and moving items. Workers should bend at the knees, keep their backs straight, and lift using their legs rather than their backs. Regular stretching and core-strengthening exercises further reduce the risk of musculoskeletal problems.

Adopting a deliberate approach, such as following the “Plan, Position, Pick, Proceed, Place” framework, enables smoother, safer material movement. Simple reminders and regular reinforcement of best practices help establish a culture of safety that all workers can embrace.

Equip Workers with Appropriate PPE

Personal protective equipment (PPE) is the last line of defense against workplace hazards. Workers engaged in material handling should always wear required gear, including gloves, eye protection, steel-toed boots, and helmets. These items minimize injuries from impacts, pinches, and falling materials. Regular inspections and proper training on the correct usage of PPE go a long way in preserving worker health.

Utilize Mechanical Aids and Motorized Solutions

Relying solely on manual labor increases the risk of fatigue and injury. Using mechanical aids like forklifts, pallet jacks, and hand trucks, and modern solutions such as motorized casters, helps reduce the physical effort required. These tools make it possible to move heavier loads with less strain, supporting an environment where workers experience fewer repetitive injuries, and productivity remains high.

Provide Comprehensive Training

No safety program is effective without thorough training. Employees should be well-versed in the correct way to lift, move materials, and operate equipment. Regularly scheduled refresher courses ensure team members stay up to date on new procedures and technologies and reinforce safe habits. Tailored programs that focus on both experienced and new staff encourage ongoing improvement throughout the organization.

Ongoing education also emphasizes how to respond in an emergency. When workers know what to do during spills or equipment malfunctions, they can act swiftly to protect themselves and others.

Maintain Organized and Clean Workspaces

An uncluttered and orderly workspace is a critical part of accident prevention. Implementing daily housekeeping routines helps ensure that aisles and pathways are free from obstacles, reducing the risk of slips, trips, and falls. Materials should always be stored securely and away from high-traffic areas. Creating a clean, organized environment also helps employees find the tools and supplies they need faster, minimizing workflow interruptions and boosting efficiency.

Regularly Inspect and Maintain Equipment

All material-handling equipment should be included in a scheduled inspection and preventive maintenance plan. Early identification of issues such as worn components or malfunctioning machinery prevents unexpected breakdowns and potential accidents. Keeping detailed records can help establish patterns, making it easier to predict when repairs or replacements are necessary.

Leverage Technology for Safety Enhancements

The rise of digital solutions is transforming material handling. Remote monitoring enables managers to monitor operations and worker safety without being on the floor, reducing their exposure to hazardous areas. Automated systems, such as autonomous mobile robots and automated guided vehicles, can efficiently handle repetitive or hazardous tasks. These innovations lead to safer operations and can make a significant difference in both large and small workplaces.

Final Thoughts

Maintaining a strong safety culture in material-handling environments is essential. By prioritizing ergonomic practices, properly equipping staff, relying on mechanical aids, investing in training, fostering organization, performing regular maintenance, and embracing technology, organizations position themselves for greater productivity and fewer incidents. The continued focus on these safety tips not only protects employees but also strengthens a company’s operational foundation.