Ten Things You Didn’t Know About 3d Scanning In Automobile Industry

3d scanning and 3d printing are the core pillars for any industry, and one such niche is the automobile sector. Any service or process you name it. These methodologies are in demand for rapid manufacturing. If you talk about 3d scanning, the market share of alone this platform is more than $ 8,427 million, and by the year 2025, it will surpass the mark of $ 53,345 million by 2025.

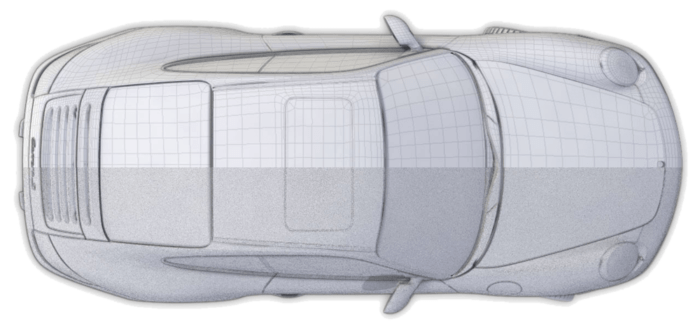

When it comes to 3d scanning in automobile, the ecosystem is very dynamic and swift. Earlier, the engineer used to draw every part and every mechanism by hand on a paper. When we peep into today’s scenario, the handcrafted desig n is still there, but now it is with the sheer power of 3d scanning. Other than this, there are tons of application of this technology, and many of them are still unknown. In this piece, we will de-compile some interesting facts and figures about the same.

Here are the top 10 things you didn’t know about 3d scanning in the Automobile Industry:

1. Scanning process elevates the printing process:

The secret behind by far and top-notch product design is not just only additive manufacturing, but it majorly involves the scanning portion. In the automobile sector, it is very crucial to have a perfect and flawless design architecture. In this scenario, only additive manufacturing is not enough. Almost 53% of product success depends on how the scans are done and up to how much depth the product is being drilled down by scanners.

So, from next time whenever you saw a beautiful piece of automobile built with additive manufacturing, don’t forget to credit the scanners as well.

2. Engineers are operating more by phones:

When we think about the big automobile industry, fast assembly lines, giant robots, and such a dynamic ecosystem, we often think about complex scanners, right? But this fact is not 100% true. As our smartphones are getting more productive and robust, companies are compiling a big chunk of work on mobile devices.

There are many robust applications are available which are capable of creating 3d cad models without requiring any additional effort. The engineer can directly push the product design from his home to the assembly line without being actually present there. Earlier, this was just a hypothetical concept, but more than 25% of the automobile work is now done on mobile devices.

3. Information is being stored in the format of scans:

Do you know how most of the automobility sector stores all the important data related to a product? If you are thinking about some documents, PDF files or some photoshop files, you are not correct though. In this era of high-tech digitalization, the majority of designs are stored in the format of ‘digital scans.’

Using BIM (Building Information Modelling), all the information is managed in an organized manner. BIM is a modern process of generating and managing all the information related to any product in the form of scans. The engineer can access any design in unordered fashion by this technique.

4. 3d scanning is not just for mapping purpose:

By its name. Many take a wild guess that this process only scans a product and give a digital and editable file to work on, but it has more to offer. By this technology, the engineers are also able to find out the “hard to reach areas.” If you are wondering what are these, hard to reach areas are portions of a design which are difficult to customize.

There could be some sort of tunnel which is hard to paint, an isolated area where it is difficult to apply some polish and so on. To make this process easier, the scanning plays a major role in it. Now you can expect pure perfection no matter how complex the design is.

5. A 3d scanned file offers more functionalities than .ps files:

When it comes to the efficiency of the prototype files, nothing can match the accuracy and convenience of a 3d scanned file. Other file formats are not equipped to hold such micro details with the support of editable functionality. This is the reason why the automobile industry leverages these high proficiency 3d scanning services to store all the data.

6. Many luxury supercar manufacturers are playing wonders:

If you are thinking about what this technology can produce, you will be surprised to know that many world-class luxury car manufacturers are leveraging these techniques to fully design their car prototype without using any external supportive tool. From high-end carbon fiber body to blade-cut alloy wheels, everything is being designed using Cad drawing service and high-tech additive techniques.

Now the engineers can make changes directly into any part of the prototype without distorting any other part of the complete structure. The rendering time is significantly slashed by this approach. If you are reading this piece from Australia and want to experiment cool things like this, there are many 3d scanning Australia hubs which can implement your idea into a beautiful reality.

7. Companies are manufacturing spare parts using this:

There are numerous spare parts which are always on high demand, but the cost of manufacturing by the traditional process is very high. To counter this problem, automobile companies are taking help of additive technologies to manufacture these parts at a significantly lower price. So, whenever you purchase any spare part for your car, there are high chances that they are made from additive methodologies.

8. Formula 1 car’s aerodynamics redesign:

Who doesn’t love speed and so formula one race? Have you ever wonder how these cars can bear such high wind pressure and achieve wind-cutting speed on the race tracks? The reason behind its science is accurate chassis design to cut the wind most efficiently. To design such complex designs, car manufacturers use high-end scanning techniques to match the performance.

9. Manufacturers are printing ‘car lenses.’

The car you drive may be more high-tech than you think and there is a reason behind it. Automobile giants are using a new technique to design and print the lenses of the car because they are high on performance and cheaper to produce. You will hardly notice any difference between the two lenses which are made up of two different techniques.

10. High-tech tyres are the future:

When the whole automobile industry is moving at a fast pace, how we can forget to talk about the tyres. The way the tyres used to build is now changed for good. Now, by using scanning and printing technologies, tyres are customized as per the vehicle’s requirement earlier this was not possible. The benefit of such sheer customization is uncompromised performance and efficiency.

These were the top 10 interesting things that you should now. We can confidently say that these above innovations are just a small beginning and we can expect something more efficient and more powerful. If you are also interested in additive manufacturing and have a revolutionary idea which can change the world, go for it. Visit your nearest 3d scanning company in Melbourne and get your prototype ready in just a couple of hours.

Author Bio: Kiran Hurkadli is the director of Zeal CAD. He is offering 3D Scanning and CAD drafting Service in Australia for the last some years. He has earned good success in the CAD drafting industry for his unique and custom designs for his clients.