How flammable liquid storage cabinets work?

Flammable liquids are used a lot when a piece of machinery is needed to move or heat something. Laboratories use Bunsen burners to fuel them, homeowners use them to fuel their cars and legislators. It can be used for heating buildings or for other uses. From earth use to flammable chemicals to scientific uses .They are among the most dangerous substances on the face of the planet.

How Flammable Works

Most flammable liquids are not in their own liquid state in flammable liquid cabinets. However, at room temperature and average atmospheric pressure they release steam in sufficient concentration, given the ignition source, they will burn easily. Flammable liquids usually have a flashpoint below room temperature and incubate at very low temperatures.

Store properly flammable

Rules for workplaces say that flammable materials should be very low in safety bins. Some flammable substances must also be contained within an intact secondary container likesecurite flammable liquid cabinets. If you store more than 25 gallons of flammable liquids – all liquids combined – you should store your liquid in a flammable storage cabinet. While the requirement is not effective, it is a good practice if you regularly store liquids that can ignite, and most people do.

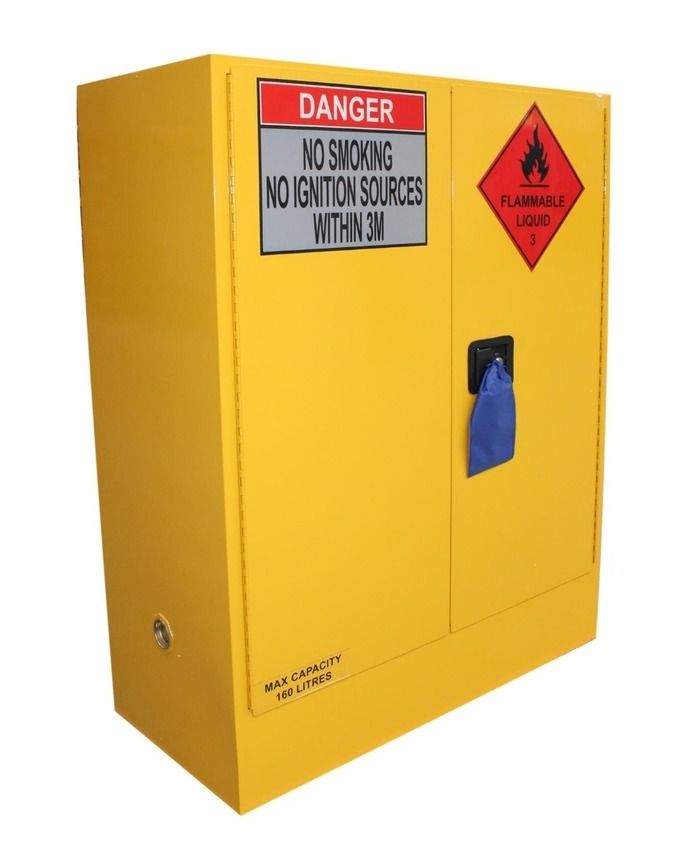

Fire safe cabinets are a great line of defense between a spark or fire and your flammable material. These cabinets are of a very visible and easily recognizable design that they include, usually in bright colors like red and yellow. These fire safety cabinets are designed to be liquid tight and around the base .Bar lips, so that in the event of leakage from the container, the liquid does not get out of the cabinet limits. Fire cabinets are also fire resistant so that any fire outside the cabinet will not ignite the contents of the cabinet.

The benefits of this cabinet are easy to see. If you have ever used gasoline to run as an accelerator, or to ignite a mesh, then you know the unpredictable and explosive nature of this liquid. Adding highly flammable liquids to any existing fire is sure to have an explosive effect, as well as spread the fire faster.

A fire safety cabinet or flammable storage locker is a good way to comply with the rules regarding the storage of flammable and combustible liquids. This is a great way to protect yourself, your colleagues and your family from the dangers of this volatile fluid.

Do you need to keep dangerous flammable liquids in your facility? Read on to learn more about how to safely store them according to legal requirements. When it comes to flammable liquids, it is important that they are stored properly. After all, most industrial combustible fires are simply the result of improper storage of such chemicals.

Luckily, there are storage cabinets that are made specifically for flammable liquids – they are also designed to be safe and to withstand heat. Also, you probably have some concerns about some of the space – and the good news is that you can get a flammable storage library that is really stackable. Those floor models fit over the flammable safety cabinets you may already have (or other safety cabinets).

You can also put it on the counter top or the work bench. This means you’ll have extra storage without losing the floor space, though you also have the option of putting those cabinets on the floor. The stackable cabinets have two doors and you can get them as a self-closing version or a manual version. But more important than convenient and floor-space saving storage options, this cabinet will protect your business from serious fire hazards. It is prudent to store all combustible and combustible materials in a proper safety cabinet. This is the law.

The regulations on Uniform Fire Code 79.202 and OSHA 29 CFR 1910.106 are very clear on their needs – and you can easily meet their requirements for a flammable safety cabinet by a quality supplier. Here is what you should pay attention to in order to ensure a compliant cabinet:

- Check for standard features that any flammable storage cabinet must meet, whether it’s a standard floor model or a stackable model.

- Look for steel construction (18-gauge) and double-walled doors with 1 1/2 “air between the sides, top, and walls. They also have 2” threaded fittings, vented fire baffles and caps.

- They should have a 2 “raised leak-proof door seal and high gloss powder finish with safety yellow-red warning labels.

- And of course, make sure they are certified to meet OSHA and NFPA Code 30 requirements.